KMLPPF

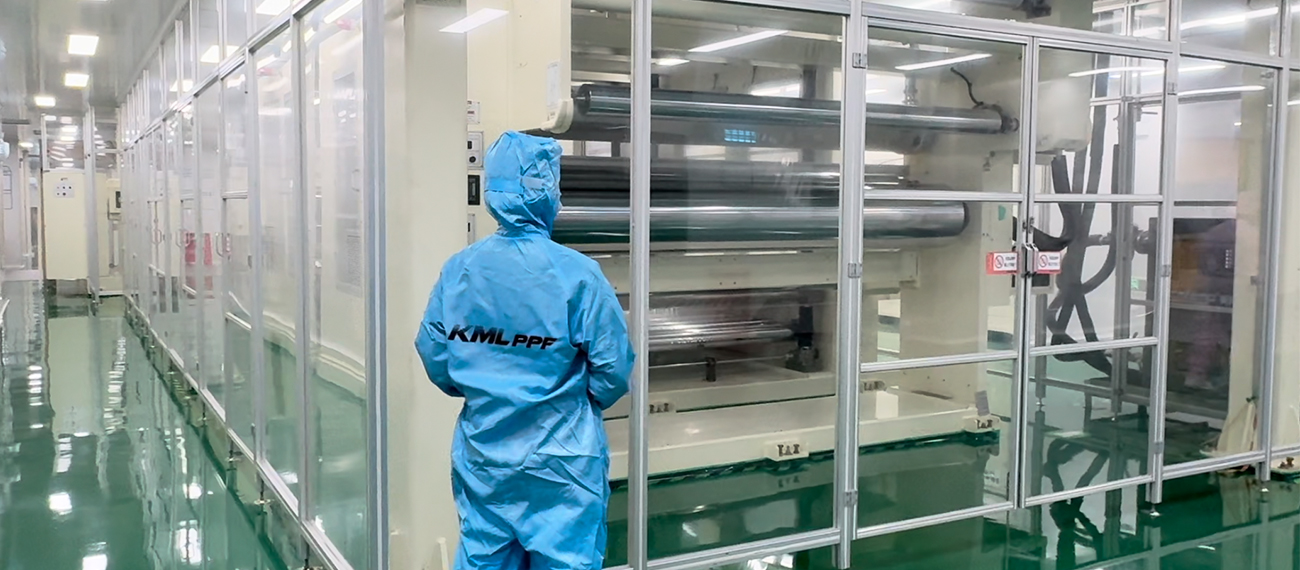

Factory Overview

Guangzhou KML Manufacturing New Materials Co., Ltd. operates a modern production base covering 500,000㎡ square meters, integrating R&D, coating, laminating, slitting, inspection, and packaging. Backed by advanced automation equipment and a professional technical team, we are committed to delivering premium-quality automotive film products.

KMLPPF

Our Products Are Sold In More Than 100 Countries

Trusted by Professionals Worldwide

Over 100+ countries choose our TPU PPF for superior protection, clarity, and durability.

KMLPPF